ABOUT US

PRAXIS ENGINEERING SILO SYSTEMS was founded in 2004 by experts in the field of Industrial Bulk Material Ηandling systems. The company provides services, from study, design and construction to installation, after sales and maintenance. Behind PRAXIS ENGINEERING SILO SYSTEMS there is a passionate team of engineers who work thoroughly step-by-step right from the very beginning of a project, in order to implement its classic solutions to the individual needs and challenges of the client and to offer a complete and ideal final result.

Our services cover a wide range of needs of the food industries and in particular in products and sectors like:

- Flour Milling

- Sugar Packaging

- Bread industries & Bakeries

- Confectionery

- Dough products

- Pies

- Pasta

- Cookies

- Ready mix products

- Sweets – Candies

CONSULTING

Non-stop collaboration, assistance and consultation between designers, sales department and customer.

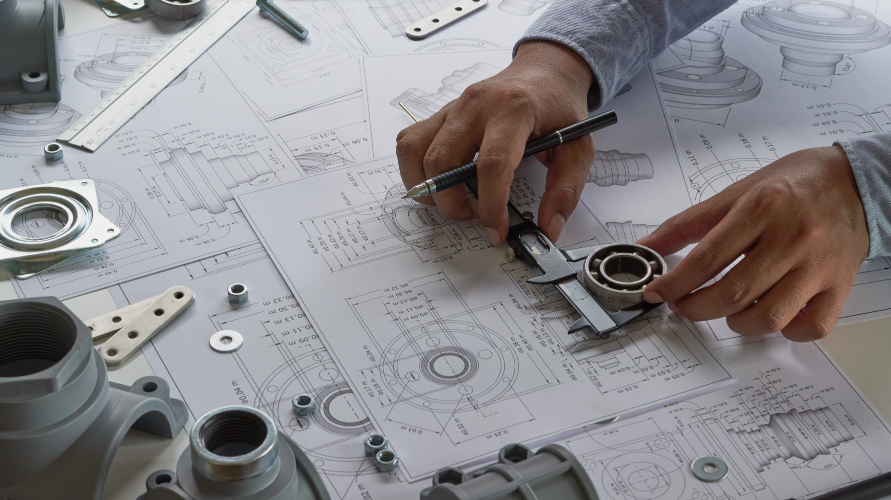

DESIGN

Systems designed by qualified engineers in compliance with the current regulations.

MANUFACTURE

In-house assemble of components, machines and management software in order to control the system automatically.

START-UP AND

POST-SALES SERVICE

Professional support from our technical team, before, during and after the installation, integrated logistics, monitoring and managing the systems remotely.